EUR

en

The total cost of pasture fencing can vary dramatically depending on the size of your property, installation method, material, and desired durability. On average, property owners can expect to spend anywhere from a few thousand dollars for smaller paddocks to tens of thousands for larger operations. Most pasture fences fall within a broad range of $2‒30 or more per foot, and fencing a single acre can cost between $2,000‒30,000, depending on the layout and chosen materials. Costs at the lower end typically reflect basic fencing on flat terrain, while more complex designs or challenging installations fall at the higher end. Additional gates, cross-fencing, and terrain variations can all influence the final total. Note that these numbers should serve as general guidelines. Real costs depend on the unique conditions and priorities of your property.

Every property and project is different, which means there’s no one-size-fits-all answer when it comes to fencing costs. Considering the key variables behind pricing will help you make better decisions about where to spend and where to save. From the materials you choose to the terrain you’re working with, these factors will determine your upfront investment as well as the fence’s long-term performance.

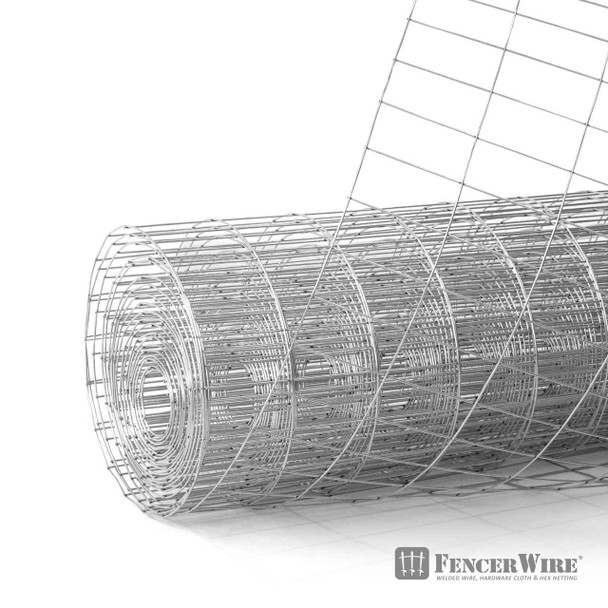

Material choice is the single biggest factor in determining the overall cost of a pasture fence. Traditional wood fencing offers a classic look but requires frequent painting, sealing, and replacement of damaged boards. Wire and electric fences are typically lower in cost initially but may lack the durability and safety needed for certain livestock. Vinyl is more durable than wood but can become brittle or fade under extreme weather conditions. High-density polyethylene (HDPE) fencing strikes the perfect balance between longevity and cost-efficiency. It doesn’t rot, rust, or splinter, and it stands up to impact without cracking. While it may have a slightly higher upfront cost than traditional materials, HDPE’s virtually maintenance-free performance makes it one of the most cost-effective choices over time.

Labor costs can account for a significant portion of your total fencing budget. Installing a fence involves planning layout lines, adjusting for proper spacing, setting posts, and securing rails or wires correctly. Complex projects with multiple corners, gates, or terrain changes require more time and expertise, increasing labor costs. Choosing HDPE fencing can help reduce those costs over time. Because the material is lightweight and easy to handle, installation tends to move faster. Pre-routed posts and pre-fabricated rails simplify setup, and since HDPE doesn’t require painting or sealing, there’s less prep and cleanup work. Whether you’re hiring professionals or tackling parts of the project yourself, the ease of installation translates into a significant cost factor.

The lay of your land plays a crucial role in determining how much your pasture fence will cost. Flat, even terrain allows for straightforward post installation, while rocky or uneven ground can require specialized equipment, deeper post holes, or more durable posts, all of which add time and expense. Wet or clay-heavy soil may also demand additional stabilization measures to prevent shifting or leaning posts. Before installation, it’s wise to have your soil tested and assess the landscape for potential trouble spots. Addressing these issues upfront through grading, drainage, or strategic fence placement can save significant money and lower maintenance costs in the long term.

Where you live directly affects what you’ll pay for fencing materials and labor. In rural areas, materials may need to be transported longer distances, which adds delivery costs. In suburban or high-demand regions, skilled labor and permits can drive up total expenses. Additionally, local weather conditions may influence your material choice. Humid climates, for instance, accelerate wood rot and rust, while areas with intense sunlight can cause certain plastics to degrade faster. HDPE fencing helps offset these regional differences because of its weather-resistant properties. It resists UV damage, doesn’t absorb moisture, and won’t corrode in humid or salty environments. No matter the location, it provides consistent performance without frequent maintenance or replacement.

Gates are often overlooked when budgeting for fencing, yet they’re essential for functionality and convenience. Each gate adds costs not only for the hardware and materials but also for installation, which typically requires reinforced posts and additional labor. The type of gate—swing, sliding, or double-width—can also affect the overall cost. Planning gate placement strategically can help minimize costs while improving accessibility. For example, aligning gates with existing roads or barn entrances reduces the need for additional fencing or driveways. HDPE gates also integrate seamlessly with fencing systems, offering both durability and a clean, uniform appearance.

Maintenance is an ongoing expense that often gets overlooked when planning a fencing project. Wood fences require painting or staining every few years, while wire fences may need periodic tightening or replacement after damage. Even vinyl fences can discolor or warp over time. These recurring costs can easily surpass the initial installation cost in the long run. HDPE eliminates nearly all of those concerns. Its color runs through the entire material, meaning it never needs repainting. It won’t warp, rust, or fade, and animals are less likely to damage it. With minimal upkeep required, the long-term savings and peace of mind are substantial, especially for large properties.

The size and layout of your property have a direct impact on fencing costs. Larger properties require more materials and labor, but they also offer opportunities for cost efficiencies through bulk purchasing and streamlined layouts. Smaller or irregularly shaped pastures often need more corners and turns, which can increase material waste and labor complexity. Before installation, mapping out your property and identifying natural boundaries like tree lines or streams can help optimize your fencing design. Strategic planning allows you to reduce unnecessary fencing while maintaining safety and accessibility, which gives you the best balance of coverage and cost.

Every customization adds to the final price tag. Electric components, decorative accents, and the number of rails all influence cost. Electric or multi-strand fences may require specialized wiring and equipment, while three-, four-, and five-rail systems demand varying amounts of material and installation time. The more rails, the sturdier and more visually appealing the fence, but also the higher the total investment. For property owners looking to balance aesthetics, safety, and budget, HDPE offers flexibility. It accommodates various rail configurations while maintaining consistent quality and structural integrity. It allows you to customize without worrying about weather-related deterioration or safety hazards common in traditional materials.

The cost to build a pasture fence can range anywhere from $2 to $30 or more per linear foot, depending on the material, terrain, labor rates, and features like gates or electrified components. On average, a small pasture might cost a few thousand dollars, while larger multi-acre installations can exceed $10,000. The average cost of fencing a single acre typically falls between $2,000 and $30,000, depending on layout and terrain. Larger properties may see slightly lower per-acre costs because of economies of scale, while smaller or more complex pastures tend to cost more per foot. While wire or electric fences usually have the lowest upfront cost, they often require frequent maintenance and repairs. Wood offers traditional appeal but deteriorates quickly in harsh weather. HDPE fencing stands out as the most cost-effective long-term option because it resists fading, rot, and damage, which reduces replacement and maintenance expenses for decades. The biggest factors include material type, labor rates, terrain, gate installations, and property size. Soil conditions, regional pricing, and design complexity also play major roles. Planning ahead and choosing durable materials can significantly reduce both initial and long-term costs. DIY installation can reduce labor costs but comes with trade-offs. Professional installation ensures proper post alignment, rail spacing, and tensioning, all of which are critical for a secure, long-lasting fence. For those experienced with fencing, HDPE’s lightweight design makes it easier to install compared to heavier materials. Plan your layout carefully to minimize unnecessary corners or crossings. Purchase materials in bulk if possible, and use natural boundaries to reduce total footage. Choosing low-maintenance materials like HDPE can also lower lifetime costs, as you’ll save on repairs, repainting, and replacements.

Bookmark

Daniel Féau processes personal data in order to optimise communication with our sales leads, our future clients and our established clients.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.