EUR

en

We propose the establishment of a Wire Drawing & Binding Wire Manufacturing Unit in the industrially growing region of Chhattisgarh. This plant will convert steel wire rods into various types of industrial-grade wires used in construction, agriculture, fabrication, and electrical sectors.

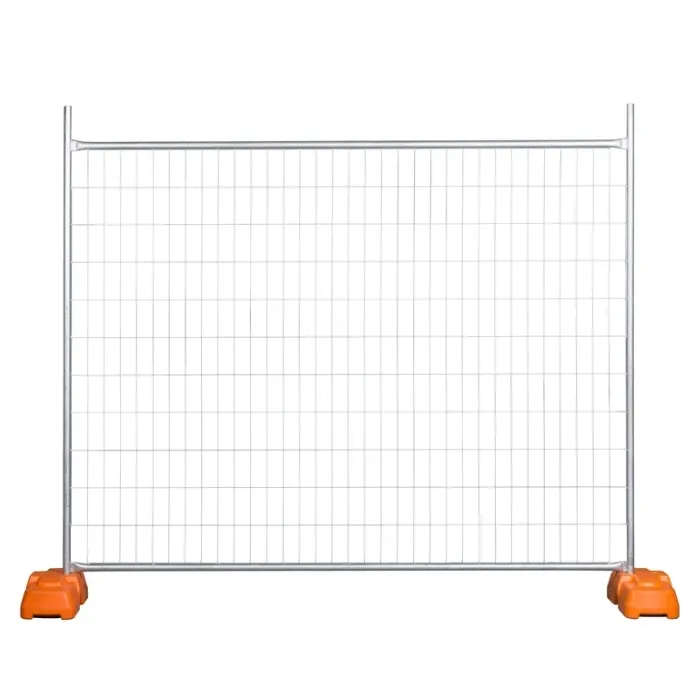

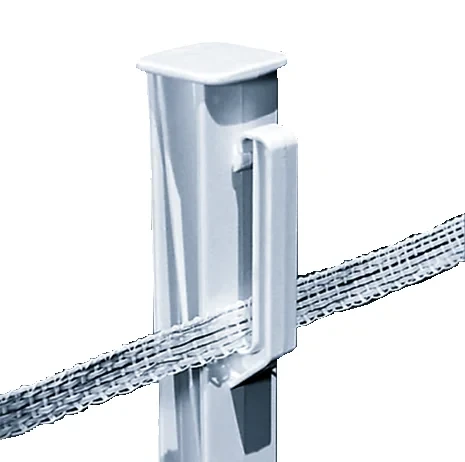

Mild Steel (MS) Drawn Wires (various gauges), Binding Wire – For construction & fabrication, Galvanized Iron (GI) Wires – For fencing, grounding, Annealed Soft Black Wires, Wire Bundles – Cut length or coiled form

Raw Material Availability – Wire rods from SAIL (Bhilai), Jindal, Monnet, Low Power Tariffs – Ideal for manufacturing, Excellent Logistics – Via NH-30 & Jagdalpur-Raipur corridor, Skilled Manpower – Industrial workforce readily available, Export Potential – Central location for pan-India and overseas shipping

Capstan-Type & Drum-Type Wire Drawing Machines, Annealing Furnace (Oil or Electric), Galvanizing Bath – For GI wire production, Coiling & Cutting Machines, Weighing & Packaging Units

Primary: Steel wire rods directly procured from SAIL (Bhilai), Jindal Steel & Power, Monnet Ispat, NMDC (Nagarnar Steel Plant – 75 km proximity). Ensures cost-effective and consistent supply chain

Low Land Cost in upcoming industrial zones, Raw Material Proximity – NMDC & local steel producers, Logistics Advantage – NH-30 & Raipur-Jagdalpur Corridor, Export-Ready – Favourable government policies & infra upgrades

Construction: RCC binding wire, Fabrication Units: Welding & fitting work, Agriculture: Fencing & crop support, Electrical Use: GI wires for grounding, Hardware Stores & Dealers: Local distribution, Export Clients: Sri Lanka, UAE, Nepal, Bangladesh, African nations

Start with: 2–3 Drawing Lines for Binding Wire Production. Scale to: GI Wire, Barbed Wire, Spring Wire, Chain Link Fence. Add-on options: Wire Nail Manufacturing, Custom Wire Bending Units

Local job creation – Operators, Technicians, Packers, Support for Transport, Logistics, Repair, & Local Services, Encourages industrialization in semi-urban areas

Land Assistance, Plant Layout Design & Installation Supervision, Machinery Procurement Support, Pollution & Safety Compliance Setup, Workforce Training & SOP Setup, Vendor Support for Raw Materials

The Wire Drawing & Binding Wire Manufacturing Unit in Chhattisgarh presents a low-risk, high-demand industrial opportunity. With guaranteed raw material supply, strategic location, and our full support, the project promises long-term profitability, scalability, and market stability.

Q1. What is binding wire and where is it used?

A: Binding wire is a mild steel wire used primarily in construction for tying rebar (reinforcement bars) in RCC (Reinforced Cement Concrete) work. It is also used in fencing, fabrication, and packaging industries.

Q2. What are the main products manufactured in a binding wire plant?

A: The unit produces various types of steel wires including: Mild Steel (MS) Binding Wire, Galvanized Iron (GI) Wire, Annealed Soft Wire, Cold Drawn Wire (various gauges), Customized Coiled or Cut Length Wire

Q3. What raw materials are needed for binding wire manufacturing?

A: The key raw material is steel wire rods (5.5mm to 8mm), sourced from local suppliers like SAIL (Bhilai), Jindal Steel, Monnet Ispat, and NMDC Nagarnar Steel Plant.

Q4. What is the typical land and power requirement for this plant?

A: Land Area: Minimum 0.5–1 acre for a small/medium unit, Power Load: 75–150 kVA depending on machinery capacity

Q5. What machinery is required to start a wire drawing and binding wire plant?

A: Capstan/Drum-type Wire Drawing Machines, Annealing Furnace (Oil/Electric), Galvanizing Bath (for GI Wire), Wire Coiling & Cutting Machines, Weighing & Packaging Units

Q6. Is this business profitable in the current market?

A: Yes. Demand for MS and GI binding wire is consistently rising in the construction, agriculture, and electrical sectors. Profit margins are favorable due to low input cost and recurring bulk orders.

Q7. Who are the main buyers or customers of binding wire?

A: Real estate developers and contractors, Fabrication & welding shops, Hardware distributors & retailers, Agricultural fence users, Exporters to Nepal, UAE, Africa, Sri Lanka, and Bangladesh

Q8. What is the production capacity of a small wire drawing unit?

A: A 2–3 line unit can produce approximately 5–8 MT/day, depending on machine specs and wire gauge. Higher capacity plants can scale up to 15–25 MT/day with more drawing lines.

Q9. Can GI wire and barbed wire be made in the same unit?

A: Yes. The unit can be upgraded to include galvanizing baths and additional machinery for barbed wire, chain link fencing, and wire nails.

Q10. What is the export potential of binding wire from India?

A: India is a major exporter of binding wire and GI wire to countries in South Asia, Africa, and the Gulf due to its low-cost manufacturing, quality standards, and fast shipping capabilities.

Q11. What government licenses or clearances are needed to start the plant?

A: MSME/Udyam Registration, Factory License, Pollution Control Board NOC (if annealing or galvanizing is included), GST Registration, Electricity Connection & Safety Compliance

Q12. What type of support do you provide in setting up the plant?

A: Land allocation, Layout planning & installation supervision, Machinery sourcing, Raw material vendor linkages, Licensing guidance, Workforce training, Buyer connection & market linkage

Q13. Can this unit be started as a small business and expanded later?

A: Absolutely. The business model is scalable. You can start with 1–2 wire drawing machines and expand to include galvanizing, nail manufacturing, or barbed wire based on market demand.

Q14. How much investment is required to start a binding wire unit?

A: For a small-scale plant, investment in plant & machinery ranges from ₹35–60 lakhs. Medium setups may require ₹1–1.5 crore, depending on automation and capacity.

Q15. What are the common wire gauges used in binding wire production?

A: Common gauges are 18 SWG (1.2 mm) and 20 SWG (0.9 mm), although you can produce custom thicknesses based on client requirements.

Q16. I want to establish a manufacturing plant in India. Do you assist foreign investors?

A: Absolutely. We provide end-to-end plant setup support for international investors and companies. Whether you are based in USA, Canada, Mexico, Brazil, Chile, Argentina, UK, Germany, France, Italy, Spain, Netherlands, Poland, UAE, Saudi Arabia, Qatar, Oman, Kuwait, Bahrain, Singapore, Malaysia, Indonesia, Thailand, Vietnam, Japan, South Korea, Bangladesh, Sri Lanka, China, South Africa, Nigeria, Kenya, Egypt, Ghana, Australia, or New Zealand – we can assist you in establishing your manufacturing operations in India.

Bookmark

Daniel Féau processes personal data in order to optimise communication with our sales leads, our future clients and our established clients.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.