EUR

en

Putting in 1/2 mile and 1 mile runs of 3 wire fence. Should I install wood post every 1/4 mile and tie off to it or tie wire together and keep on. This is on gently rolling ground. TIA

On straight and level, I like a good 'H' brace at least every 1/4 mile. Ridge tops, coulee bottems, bends also call for braces. A little more time and material--but I've got fences I built 40 yrs ago that have had maybe 10 hrs maintenance, per mile--total--- since.

What littlejo said! I'd also consider a wire gate every 1/4 mile and a 4th wire if it is an exterior fence, especially if it'll have calves against it.

I am just curious, do you run a lot of three wire fence now? If what you have is working, just duplicate it. Fencing seems to be awfully location specific.

Nah, just lost of locations do a poor job of fencing.

Set an H brace every quarter mile. I only like to stretch in quarter mile increments. Plant your corners 5 feet deep, put brace pipe just above the middle, double 9 wire or horse cable, twist it tight, leave twister in. The H braces in the middle of the line can be a little smaller posts, but must be 9 foot minimum. Cross brace them, twisted tight. Corners make your fence! You will waste all your money and labor in between them if you don't do them right!

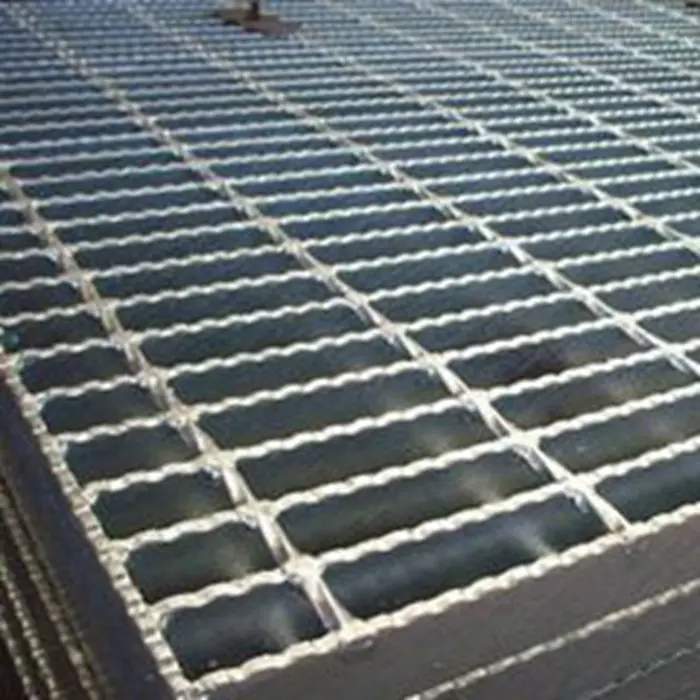

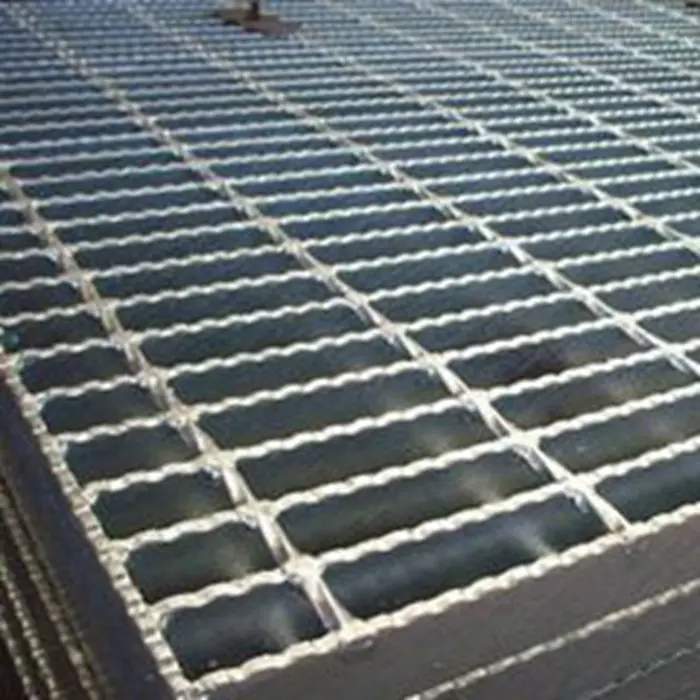

Here's a pic.

No advantage putting that brace pipe that low, with that being said that corner won't pull out. BUT engineering wise taller brace pipe is better. 5 1/2 pipe 10'x10' with a shorter kicker 10' out (corner post hole belled out with minimum 12" auger) is better than any hedge.

I have absolutely NEVER understood the purpose of intermediate braces in a line fence. Just install good brace posts wherever you want a gate and at the ends. Otherwise let the wire maintain tension in between which is easy to achieve with wire grabs on a block and tackle or even a ready rod stretcher.

mccoyranch - 8/15/2017 21:35 Set an H brace every quarter mile. I only like to stretch in quarter mile increments. Plant your corners 5 feet deep, put brace pipe just above the middle, double 9 wire or horse cable, twist it tight, leave twister in. The H braces in the middle of the line can be a little smaller posts, but must be 9 foot minimum. Cross brace them, twisted tight. Corners make your fence! You will waste all your money and labor in between them if you don't do them right! "put brace pipe just above the middle" Lotsa folks believe this, I've been contrarian on it for 40+ yrs. How many h braces you've seen that gave, both posts leaning thataway---pole in middle kinda a pivot? I put up to top of post. Draw it out----now you got 2 triangles, and it's way stronger. Some guys will put brace pole hi on corner and lower heading down fence. Some will brace from top of post to ground. Either will act like fulcrum to jack post outa the ground.

Good fences last because of well built braces and stretching the wire tight. You should need pull h's every 1/4 mile to keep from breaking wire and having spices. They also lower the strain from temperatures causing expansion and contraction. If you can run a mile of fence with a pull and it doesn't break, you ain't got it tight enough.

+1 except the H part, a single hedge post should be enough with tension both ways. Or a metal with kickers or really a single metal. IMO hate splices

I'll reuse wire if it'll splice. Our climate, wire lasts a long time, if it hasn't been in the dirt. I've tied new wire onto old wire, stretched it till it broke and it was the new that broke. About the best old wire is wire salvaged off of RR right of way fence. I use old wire for gates---lays flat. And make the last 3' of top wire barbless---saves tears on clothes and scratches. Takes a lot of ground to run a cow in windy 12-14" precip area---some gates only opened a few times a yr, 99% are barb wire. Still got some with 'spurs', water right on that place is 1875. Jacks, too. Still got some with square nails and hand pegged. But they do get a little shorter~!

ntex you and I disagree on certain laws of physics. How is a wire less likely to break when tied to a post than it is spliced to the rest of the fence? My system might not work well if there is a lot of vegetation snagging the wire.

My .02 To SWND's original question, I would stretch every 1/4 whether it be to a single well set post or an H brace. Like ntex said, it's to difficult to get the wire stretched tight with the resistance of the wire dragging across the ground unless you have several teenage boys running back and forth throwing the wire up in the air to get the slack out. I built a 1/2 mile years ago w/o any braces in between just to see if I could and I had my help go down the fence driving a T post every so often while I watched with binoculars from one end to the other to guide him left or right so we could get the first wire straight. It's just not worth it. I understand what happytrails is saying, if you have a intermediate brace with equal and opposite forces acting on it, then what's the point? The point is for convenience in construction I believe. With regard to the position of the horizontal brace, it doesn't matter where it is located. The mechanical advantage remains the same, only changes if you were to place horizontal brace at a angle other than horizontal which you don't see very often and is not a good idea imo. In the diagram you see that if you move point A a theoretical 1.00" with C and F being pivots then point C still attempts to move the same amount of .900"(approx.) in both structures. As you move the horizontal brace up or down the mechanical advantage you gain on one end is cancelled out on the other end keeping the M.A. at or near 1:1. I personally like the horizontal brace in the middle (like Mccoyranchs brace) as it (the horizontal member) seems to stay in place better (because of the mechanical advantage the cross wire has to hold it in place) but it is personal preference only. All brace designs will fail if there are enough wires stretched tight enough, only they fail differently....both post lean....corner post pulled out..whole brace rotated out of the ground..etc. Take notice of the different designs as you drive around the country. The one exception I've seen to this rule is steel post H brace welded up rigid (two or more horizontals) concreted in with holes BELLED out at the bottom which takes more work than most people are willing to do including me. Now watch, a week from now someone will ask the same question, I'm out!!!

Well, Ok. Barb wire comes in quarter mile rolls, so it's convenient and seems to work well to pull every quarter mile. The braces at at or near the top, when wire is pulled tight, put upward pressure on the corner. Look at old fences with braces at the top and the corner is pulling out of the ground. Putting it in the middle equalizes the pressure on the 4 parts of the H brace. Mine shift away from the pull when I twist the brace wire tight, then come back when I stretch all 5 wires. Hence, I feel I have equalized the pressure between the two posts. As Tight as I stretch the wire, an un braced corner would move. I see an older farmer who built new fence with small corners, short brace pipe up high, and a golden rod stretcher. 5 years later his fence is loose, posts are leaning, and wires come off line posts. As a fence contractor, I refuse to pull used wire. I know it is still good, and yes, it should not be thrown out. Personally I have kept some off fence jobs to use on rented pastures. My experience is that when I start to pull it, there will be weak points from kinks, or splices, and it will break. Sometimes more than once. Then I am running back and forth wasting time. It is also back breaking labor to try to un roll it, or drag it back to the fence line. I do not carry hand diggers, or the bar style golden rod stretchers; you just won't get it tight with those.

I wasn't disagreeing with you.

what are you using to stretch your wire. We use a cable winch that is chained to the brace post and then has a metal ring that connects the barbed wire and the cable. I still run out of juice sometimes before it could be as tight as it could be, but you can bout play a tune on the barbed wire if its flat. If its rolling ground you have to be careful because you can get it to tight and then you cant get the dang wire down low enough to screw it to the post or clip it.

I start with a chain strainer, modified to handle barb wire, to get started and get the slack out. It has a 4 foot pull, then I finish with the dual action Come-a-Long. I can break the wire with that, so I've got where I kinda know when to stop. Rolling ground is tough. I may hook a stretcher at each end, start at the worst low point that I can barely get in the post notch, then work out from there. Sometimes stretching and letting pressure off as I go.

Bookmark

Daniel Féau processes personal data in order to optimise communication with our sales leads, our future clients and our established clients.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.