EUR

en

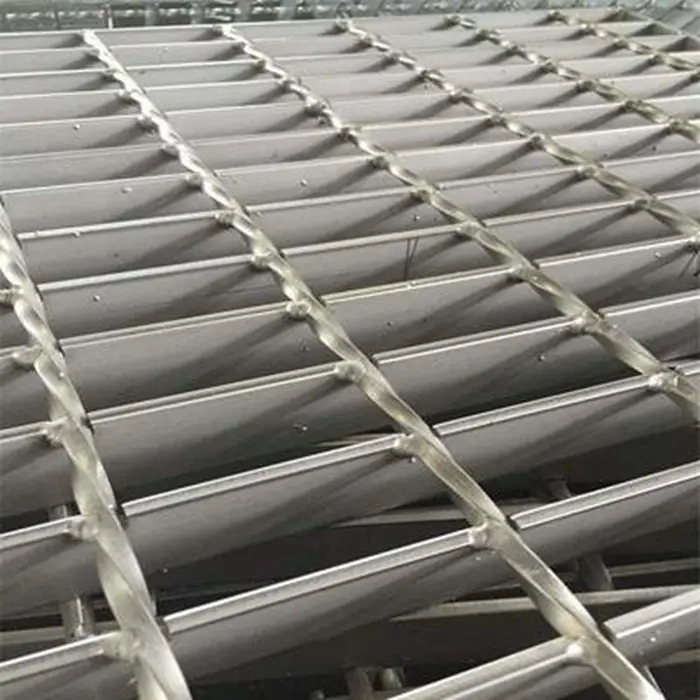

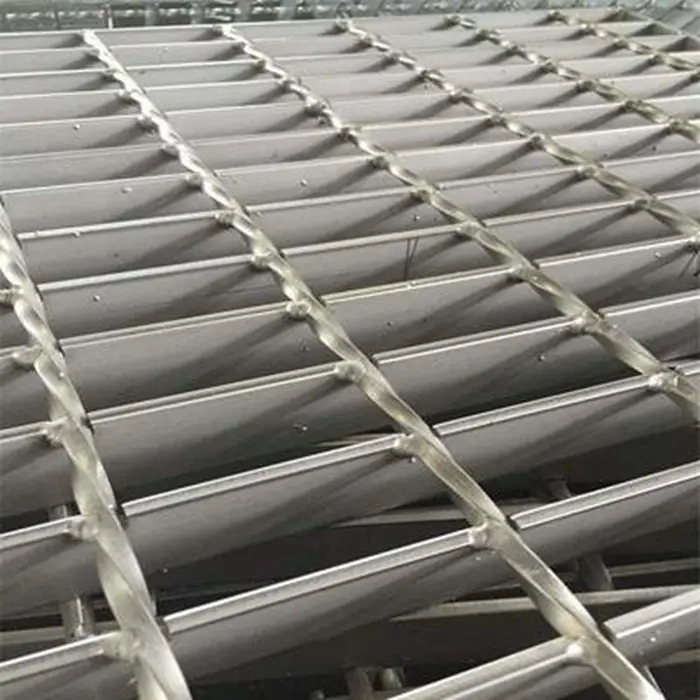

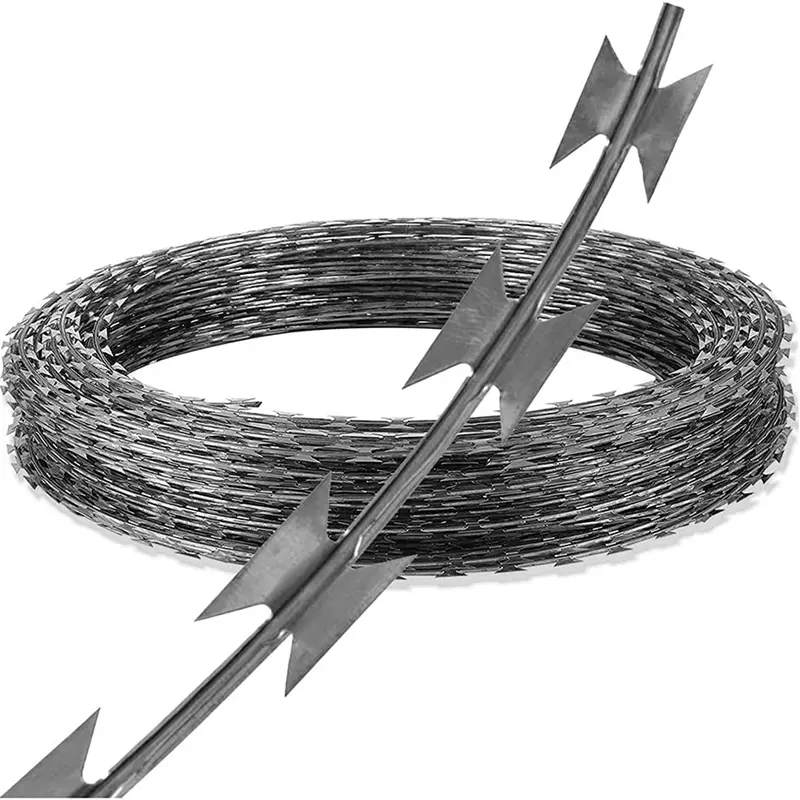

Galvanized metal mesh is highly regarded for its versatility, cost-effectiveness, and durability. The galvanization process involves coating the mesh with a layer of zinc, which protects it from rust and corrosion. This makes galvanized wire mesh suitable for thousands of applications, offering a longer lifespan than non-galvanized options.

Galvanized wire can be woven, welded, and polycoated, with galvanized welded wire mesh featuring bonded intersections at each wire junction.

There are two main methods for galvanizing iron and steel wire: hot dipping and electrolytic reactions. In hot dipping, the mesh is submerged in molten zinc, creating a strong protective coating that prevents rust, ensuring long-term functionality. Cold galvanizing involves applying a zinc-rich solvent to the mesh, which evaporates to form a rust-resistant coating. While more cost-effective, cold galvanizing typically offers less protection than hot dipping, particularly at wire intersections.

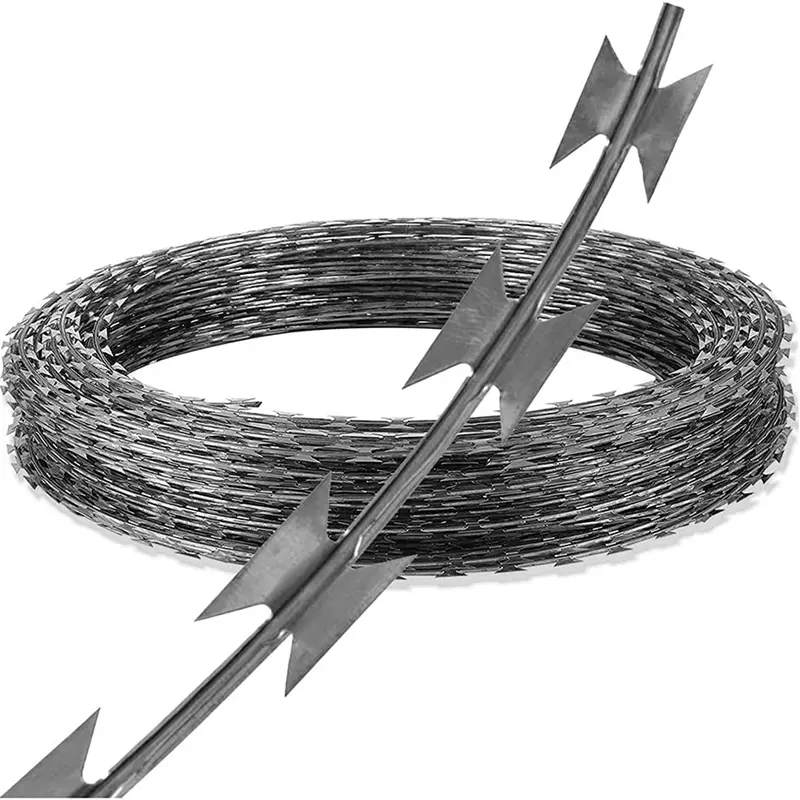

Galvanized wire mesh is used in a wide range of applications, including:

By being galvanized before or after fabrication, the mesh gains enhanced durability, particularly at wire intersections, making it a reliable material for a wide range of industrial and construction needs.

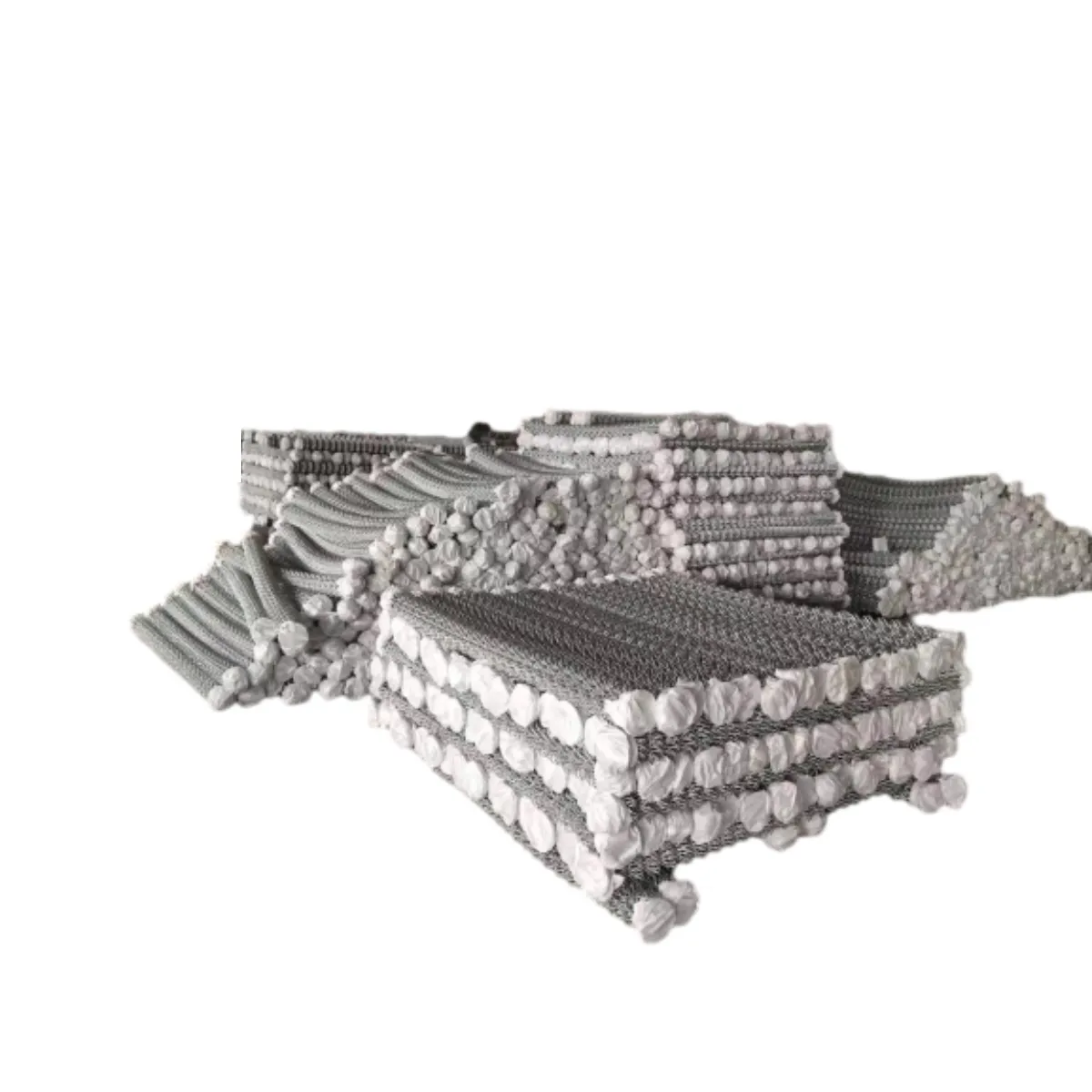

Galvanized woven wire mesh discs and galvanized welded wire mesh discs are highly versatile and durable, making them ideal for a wide range of industrial applications. Their corrosion resistance ensures long-lasting performance in demanding environments. Some of the key uses of galvanized wire mesh discs include:

The robust nature of galvanized wire mesh discs makes them a practical solution for filtration and separation in critical industries.

Galvanized mesh rolls, discs, and cut pieces are an excellent choice for a wide variety of projects due to their durability and relatively low cost. Here are some of the key applications:

With its versatility and durability, galvanized mesh is a practical solution for both functional and aesthetic needs.

Need a custom size for your project? TWP Inc. offers in-house wire mesh laser cutting, delivering accurate, efficient, and budget-friendly results tailored to your exact needs.

Bookmark

Daniel Féau processes personal data in order to optimise communication with our sales leads, our future clients and our established clients.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.