EUR

en

Introducing the most comprehensive on-line gabion retaining wall size and pricing configurator with over 100 gabion size variations and configurations to suit any retaining wall project.

The easy to navigate gabion configurator allows you to choose preferred gabion weld mesh aperture, gabion length, gabion height and gabion depth.

Gabions can be used for a multitude of tasks in building, construction, landscaping and outdoor features.

Our gabions are Australian made and conform to the highest quality and standards no matter what the size project.

A gabion structure is commonly known as a gravity wall meaning the internal weight of the structure is forced back down into the earth giving incredible retaining advantages.

Effectively a gabion retaining wall utilises its own weight to resist lateral earth pressures.

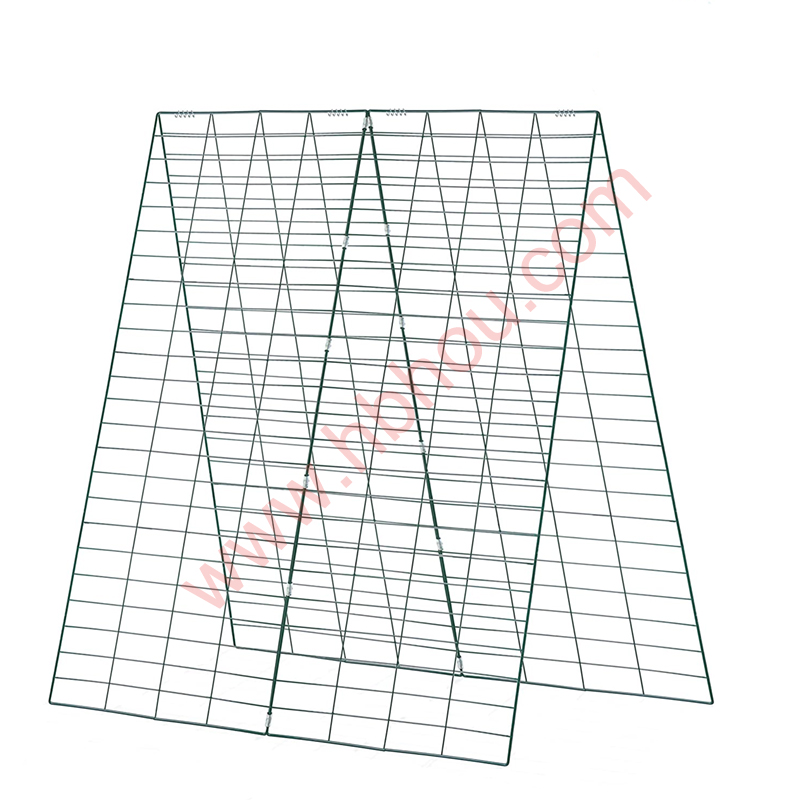

Weld mesh gabions such us Urban Kubez maintain form, stability and strength when installed individually or linked together.

To assist with your project each and every gabion we sell has a pre-determined quantity of internal bracing wire supplied as part of the kit. The braces are 4mm with bezinel coating, pre-formed hooks which assist the build quality and overall safety by supporting the facing panels of the gabion ensuring they remain straight and free from bulging.

Gabion retaining wall systems will not experience shifting, cracking, splitting or any major deformation and require no on going maintenance.

As part of our service we supply upto 30-50% more braces than our competitors at no extra charge.

In addition each gabion kit comes complete with heavy duty spiral wire to link the panels together. The spirals are simple, efficient and extremely strong way to form up gabions.

Another key advantage with gabion walls is their _**“free flow”**_ drainage ability. By allowing water to flow through the gabion and internal rock material, gabion retaining walls will not experience hydro-static pressures (water build up behind the structure) which is common in other retaining systems.

Retaining Walls with Capabilities to exceed 5m height

Free Standing Wall | Feature Wall

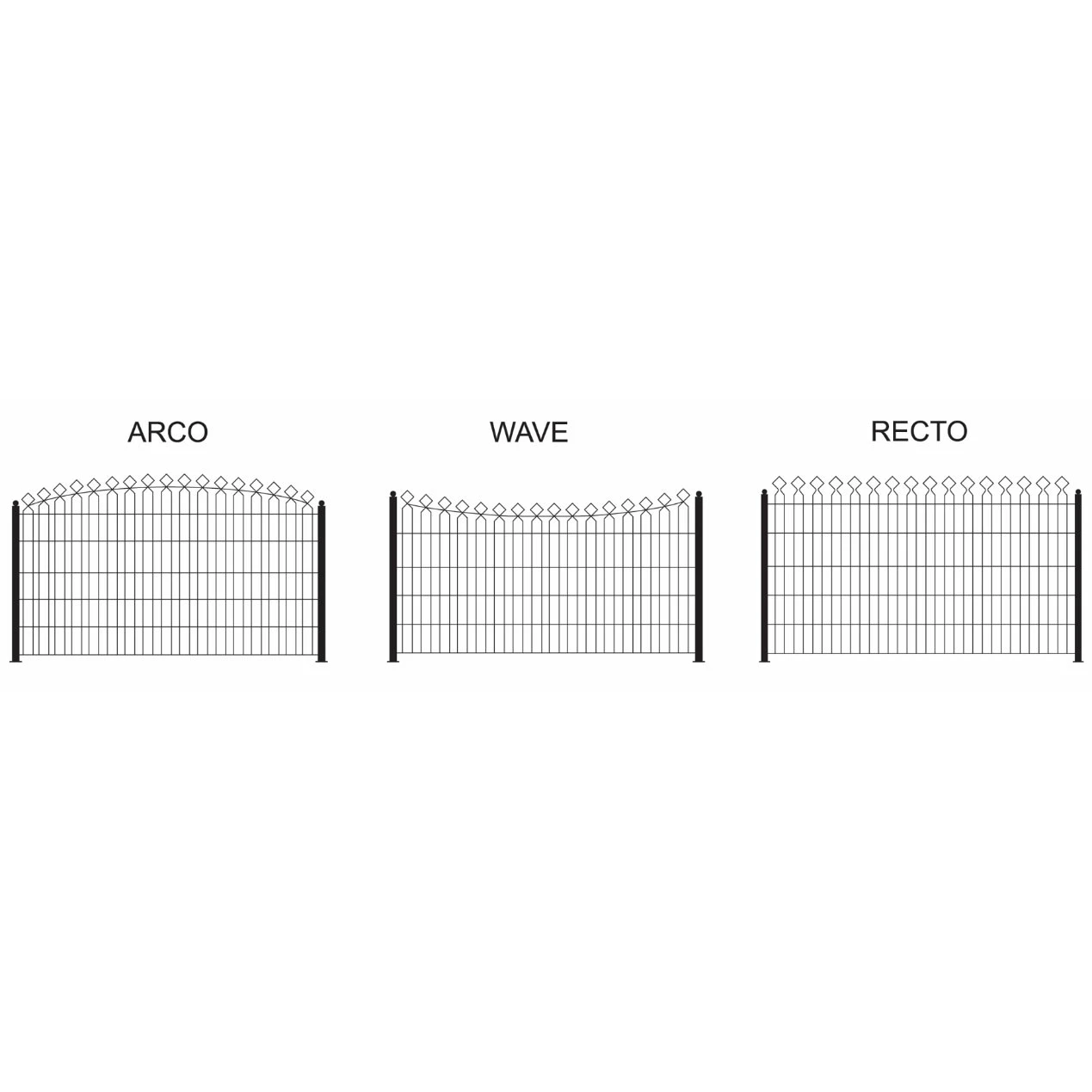

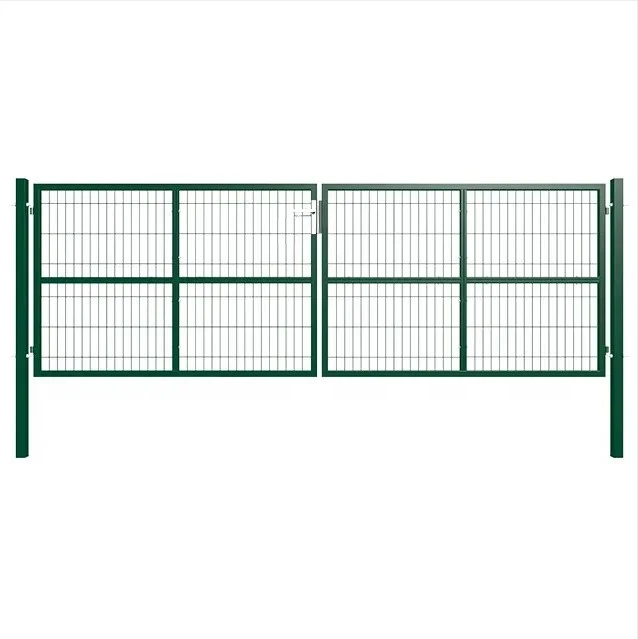

Fences

Noise Barrier

Path | Driveway Borders

Garden Edging

Seating

Plant Stands

Planter Boxes

Pylon | Piers | Post Wraps

Letterboxes

Feature Towers

Industry Leading Wire Tensile Strength (600+Mpa)

Bezinal 2000 Coating (Genuine Licensed Bezinal 2000 Coated Wire)

International & Australian Standards Compliant (ASTM974-97)

Suitable For Architectural & Civil Projects

Material / Coating Data Sheets Available Upon Request

ISO 9001/2008 Quality Manufacturing

Local Stock Holdings For Time Critical Projects

4 panels 1000×500

2 x panels 500×500

4 x 1 metre spiral wire (4mm bezinal coating)

8x 500mm spiral wire (4mm bezinal coating)

5 x internal braces (Pre formed hook, 4mm bezinal coating)

Architectural Landscape Designs & Features

Free Standing Walls & Fences

Retaining Wall Structures

Erosion Control

Civil Works

Bezinal® coated wires resist corrosion 2 to 6 times longer in heavily polluting corrosion tests than hot-dip galvanized wires and last up to 8 times longer in heavily polluted areas**. This is thanks to the formation of the dense and high quality passivation layer that is mainly formed by aluminum oxides.

** Based on salt spray tests and Kesternich tests

Zinc-alloy coatings also offer cathodic protection of uncoated areas of the steel (e.g. cut-ends or scratches). The active coating generates an electrical current which reverses (counteracts) corrosive attack of the steel.

Regular hot-dip galvanized (HDG) wires tend to experience alloy layer growth when exposed to higher temperatures. This alloy layer is the interface between the metallic coating and the steel wire. It generally contains the elements of the top coating combined with iron from the wire core. However, coatings of the Bezinal® range are immune to this phenomenon due to an inhibiting action of aluminum.

To ensure the good quality and performance of our products, Bekaert constantly performs various standardized tests for product development or on the specific request of our customer. Bekaert performs corrosion tests from their own ISO 9001 certified laboratories and has them confirmed by various independent research facilities across the globe.

Prepare level and solid ground, for best results compact road base is recommended to ensure the foundations are solid and the gabionsits flat. This step will also assist project aesthetics with accurate and straight panels.

For gabionretaining wall situations utilise geo-fabric behind the gabion to ensure soil does not wash through the wall. Drainage gravel behind the wall is also a great option particularly for large walls 1m and above.

Assemble gabions and link end to end. One end panel can be made redundant if desired without affecting the integrity of the structure.

Place bracing wires internally and close the hook end using pliers. Braces keep the panels tight and straight otherwise the panels will bulge outward when filling with stone.

Hand packing stone into thetightly will ensure the gabion is solid, safe and aesthetically impressive. Use angular type stone such as granite or basalt

Fill the gabions gradually and progress to include the next gabion rather than completing each one individually.

Retaining walls over 1m in height may require local council approval and potentially engineering certificate.

Bookmark

Daniel Féau processes personal data in order to optimise communication with our sales leads, our future clients and our established clients.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.