EUR

en

Concrete reinforcement strengthens the material by improving its tensile strength, the ability to resist stretching or pulling forces. While concrete is naturally very strong under compression, it’s much weaker under tension. That imbalance is what causes cracking when concrete expands, contracts, or shifts under pressure.

Adding reinforcement like wire mesh or rebar helps balance those forces. When a slab experiences stress, such as temperature changes, ground movement, or heavy loads, the reinforcement absorbs the tension, preventing concrete cracks and separation.

Reinforcement also increases the load-bearing capacity of a slab. That means it can safely support heavier weights without losing strength or stability. The right reinforcement keeps the slab together even if small cracks form, helping it maintain a level surface and a long service life.

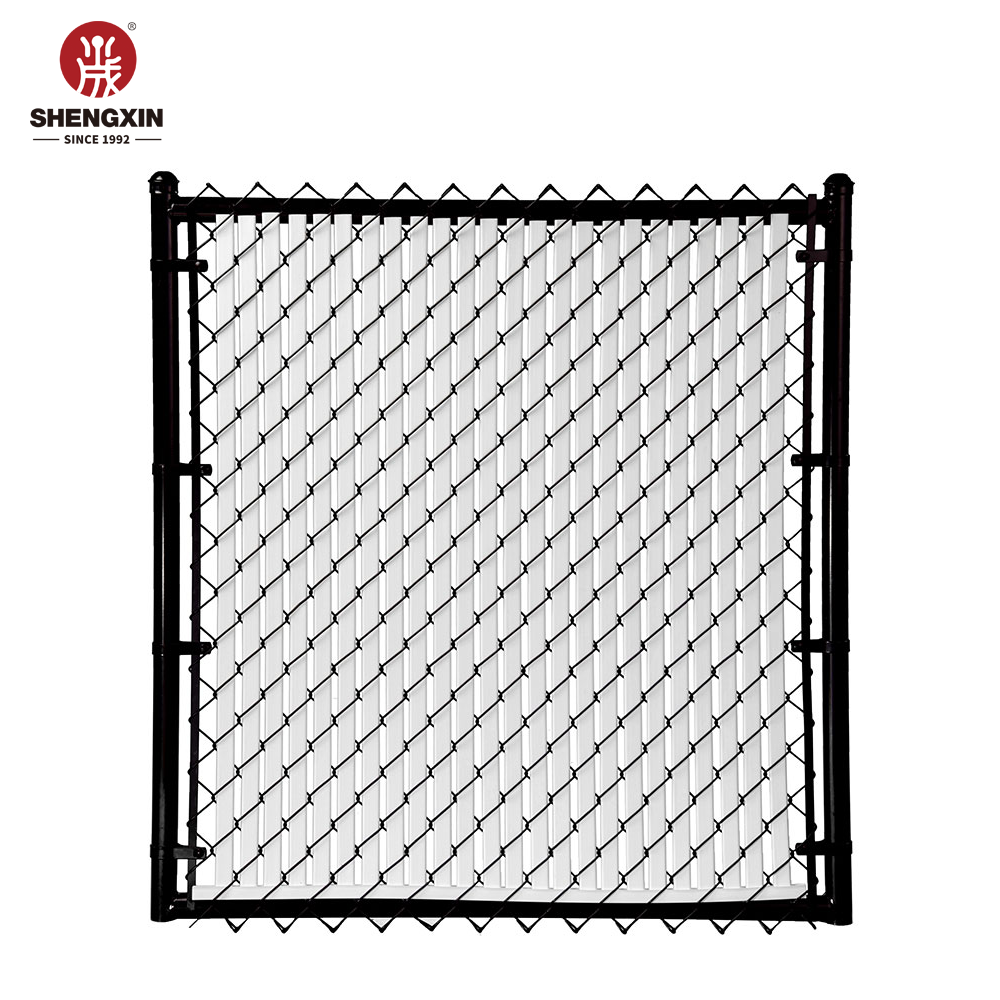

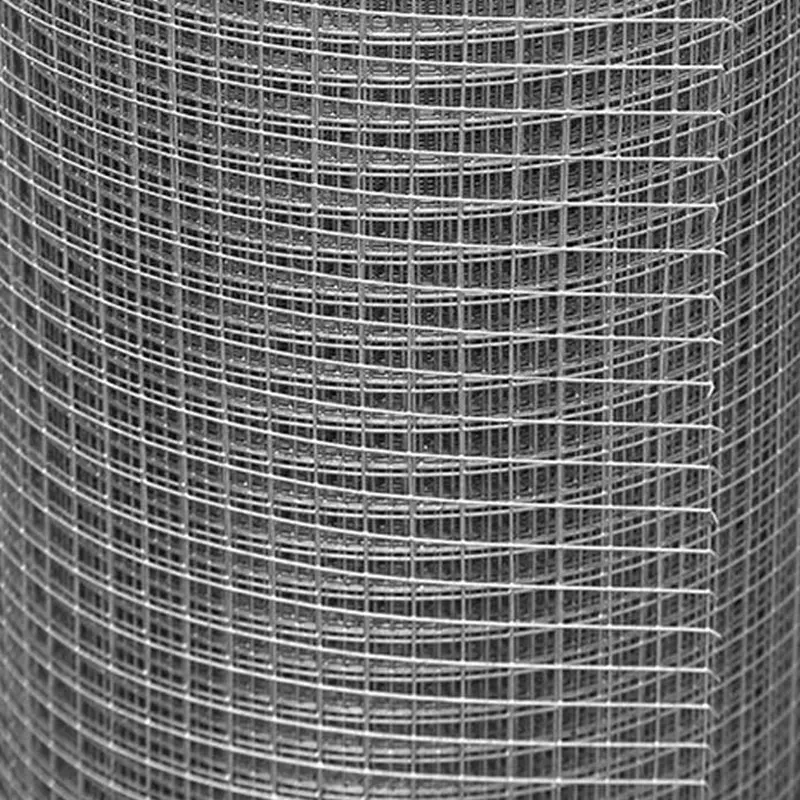

Wire mesh, also called welded wire fabric, is made of steel wires welded together in a grid pattern. It comes in rolls or sheets and is available in several forms:

Wire mesh reinforcement works well in situations where the concrete doesn’t need to support heavy loads. It’s most often used in:

Rebar (short for reinforcing bar) consists of ribbed steel bars that create a solid framework inside the slab. These bars interlock with concrete, increasing its ability to handle tension and prevent large cracks.

Common types include:

Rebar comes in different sizes and gauges, with higher grades offering greater tensile strength and load capacity.

Rebar is best for high-stress or load-bearing projects. Choose rebar when your concrete needs to handle heavy loads or expansive soil.

Common uses include:

Rebar has higher tensile strength, allowing it to withstand bending and heavy loads without cracking. It’s ideal for thick slabs or foundations where the structure must bear significant weight.

Wire mesh provides basic reinforcement that holds the slab together if small cracks form. It’s best for lighter applications and projects focused on preventing surface defects.

Rebar typically comes with a higher upfront cost and requires more time to install, but it delivers superior strength and long-term reliability for demanding environments. It’s the better option for commercial projects, large slabs, or areas exposed to heavy traffic.

Wire mesh is more affordable and easier to install, making it popular for residential or DIY projects. It’s lightweight, flexible, and can be rolled out quickly, which saves time on smaller pours while still providing adequate crack resistance.

Using wire mesh where heavy loads are expected can lead to cracking or slab failure. Always consider the traffic type, soil condition, and slab thickness before deciding.

Both wire mesh and rebar must be embedded properly in wet concrete, not resting directly on the ground.

Wire mesh may seem like a cost saver, but it’s not suited for commercial projects with frequent heavy loads. Conversely, rebar may be excessive for light-use patios or sidewalks.

Use wire mesh for smaller slabs and projects that don’t require high structural strength. Choose rebar for heavy-duty applications where long-term durability and load-bearing capacity matter most.

Bookmark

Daniel Féau processes personal data in order to optimise communication with our sales leads, our future clients and our established clients.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.