EUR

en

Though there are many ways to bind your documents together, wire binding is one of the most popular methods. Synonymous with wire-o binding and twin-loop binding, wire binding feeds thin wires through punched holes to bind documents together. The result is a sleek, durable finish popular for various applications.

While wire, comb, and coil binding have a lot in common—especially compared to thermal binding—they have some key differences.

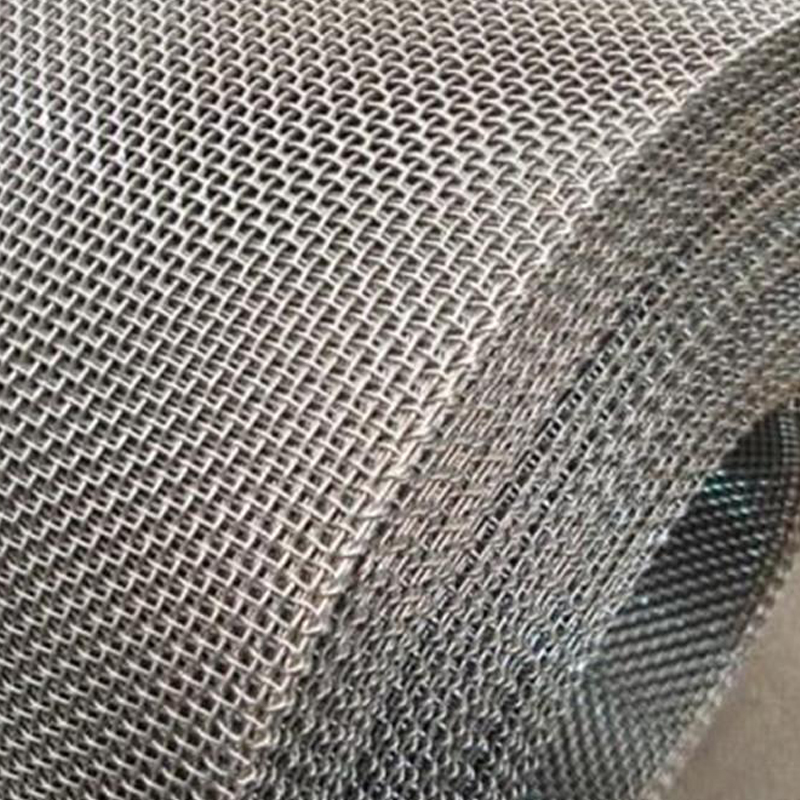

A wire-o binding machine uses metal wires to hold pages together, but coil and comb binding machines use plastic. But for most end users, the most salient difference between double loop wire binding and other methods is appearance.

While plastic coil binding looks much like the spiral notebooks we know from school, the double steel loops used in wire binding look more sophisticated. Comb binding has a printable surface on the plastic comb that holds the papers together, allowing for titles or text to be printed on the side.

Of course, that’s not doable with coil and wire bindings. But they both allow for pages to rotate 360 degrees, which isn’t possible with comb.

A wire-o binding machine can make corporate reports, proposals, manuals, employee training books, and more. You’ll also see wire binding used for educational documents like dissertations and on consumer goods like planners, notebooks, and calendars.

Many corporations, non-profits, and educational institutions use wire binding. In particular, many architects, engineers, graphic designers, and financial analysts rely on wire binding to make polished-looking, affordable documents for clients and internal teams.

Wire binding can hold up to 300 pages, depending on your punch pattern (pitch) and wire diameter. Wire-O traditionally comes in two “pitches” or hole spacings. 3:1, which has three holes per inch of paper, and 2:1, which has two. Pronounced “three to one,” this pitch is used for smaller binding wires up to 9/16” in diameter. The holes are traditionally square. “Two to one” pitch is used for the larger wires from 5/8” to 1-1/4” diameter, conventionally. However, some manufacturers now make this same pitch in the smaller sizes. The benefit of this? Being able to bind the full span of wire sizes with just one punching machine. But the downfall? The look of 2:1 pitch spacing for small wires can feel a little odd. Holes for 2:1 wires are usually square, but can sometimes be round.

Simple steps to get the proper fit for wire binding.

Note: the capacities listed below are approximations, determined using standard 20 lb. bond copy paper; the actual sheet capacity will vary depending on the materials being bound.

Note: The smaller 2:1 pitch wires from 1/4" up to 9/16" are a special-made wire, and are not available in all colors.

Beyond size options, you can pick from over 10 colors (and sometimes more, depending on the manufacturer) for the coating on the loops. From gold wire-o binding to red, green, or blue, options abound. This makes it easy to match your unique branding; but if you cannot match it, a clean white, black, silver, or pewter look great with any color scheme.

There are many different double loop wire binding sizes, and you can even order custom lengths. While the range of stocked lengths to choose from is limited, cut-to-length wire-o binding can allow you to bind whatever length document you want. When requesting a custom-cut wire quote, you will need to know: (1) the diameter of wire you need, (2) the pitch, (3) the number of “loops”/correlating holes on your binding edge. Before you start, punch a sample of your document and count its holes to help determine the length you need.

Wire binding has many benefits, but the biggest is aesthetic. Its dual metal loops make documents more pleasant looking than comb and more polished looking than coil. Of course, coil binding looks sleek, but it can create a more notebook-like appearance relative to wire binding. It’s no surprise that wire binding is so popular for professional documents.

Wire binding can flex a bit more than comb binding with use, and can open 360 degrees, like coil binding, making it perfect for manuals, cookbooks, and calendars. It also has perfect registration, meaning that even when opened all the way, the front pages and back pages align perfectly and are not askew like they are with a spiral coil. If you need frequent flipping, wire binding could be perfect for your needs.

Even though wire binding makes for professional-looking documents, it has some disadvantages. Because the loops are metal, wire binding spines can be bent or damaged if they aren’t properly stored (picture Bob from accounting dropping a full water cooler jug on your stack of quarterly reports). Even though wire bindings are made of steel loops, the metal can be bent without much effort. In comparison, because coil bindings are typically plastic, they will return to form just fine.

The colors available are also on the professional spectrum only, so more exciting and fun colors are not traditionally available unless you need to order production-level quantities and choose a custom-manufactured color.

Beyond material qualities and colors, wire binding is a little more expensive on the consumable end and takes longer to do than comb binding.

Wire binding can be complex. Below, we’ll answer some of the most commonly asked questions about this method.

It might seem counterintuitive, but you can—with the right gear. A specially manufactured Spiral-O Wirewill allow you to use wire binding with the comb punch pattern. But you will still need a wire closer.

It depends on factors like the desired aesthetics, type of document, and size of the document. Both are durable and sleek, but some feel that wire binding imparts a more professional look. Coil is much more durable over time, though.

Yes, our Wire-O bindings are Prop 65 compliant.

Yes, 2:1 pitch can handle many double loop wire binding sizes, including the largest 1-1/2” size.

By now, you should have a good feel for the basics of wire binding. No matter what you call it–wire-o binding, twin loop, or double loop wiring binding—this method has an illustrious reputation for a reason. So whether you’re a twin loop ninja or a newbie, if you care about presenting your work in its best form, look no further than Binding101 for your wire binding needs.

Bookmark

Daniel Féau processes personal data in order to optimise communication with our sales leads, our future clients and our established clients.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.