EUR

en

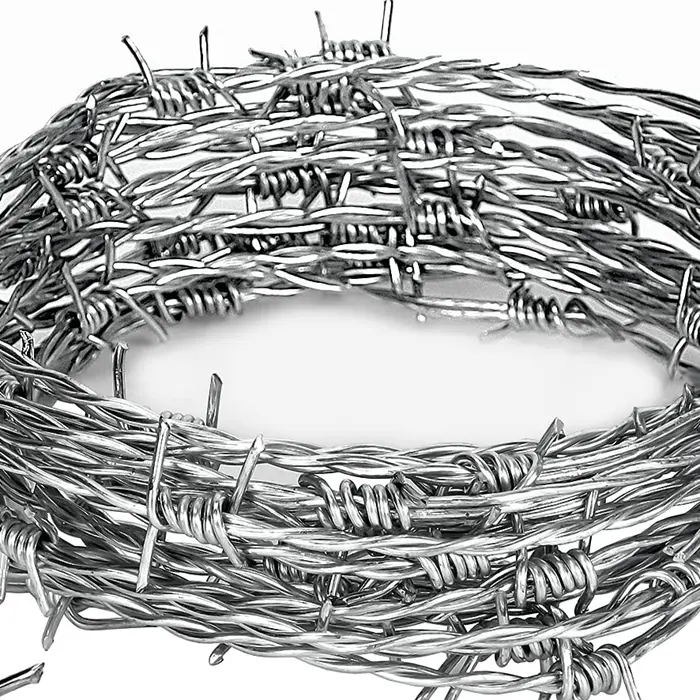

Stitching wire is a type of metallic wire used to bind printed materials by driving it through the paper to form a staple-like fastener. Unlike plastic or comb bindings, stitching wires provide a permanent hold, making them ideal for high-volume or professional print applications. Most commonly made from galvanized steel, stitching wires can also come in stainless steel, tinned, or coated finishes depending on the application.

Wire stitching is commonly used in saddle stitching machines, loop stitchers, and other commercial finishing equipment. It’s the preferred binding method for magazines, catalogs, newsletters, and smaller booklets due to its speed, cost-effectiveness, and strength.

Stitching wires vary based on material, thickness (gauge), and finish. Here’s an overview of common types:

The gauge typically ranges from 21 to 25, with thicker wires used for larger stacks or heavy-duty documents. Always consult your binding machine’s specifications to determine compatible wire sizes.

Wire stitching can be applied using manual, semi-automatic, or fully automatic stitching machines, depending on the production scale. Here’s how the process typically works:

First, the machine feeds the wire coil into its stitching head in preparation for binding.

Next, the machine cuts the wire to the required length and shapes it into a staple-like form.

Third, the machine drives the formed wire through the stack of papers and clinches it securely at the back to hold the pages together.

And lastly, some machines also perform trimming or folding as the final step to complete the booklet.

There are two common stitching techniques:

Binding is the process of securely fastening individual sheets or pages together to create a single, organized document such as a book, booklet, manual, or report. It’s an essential step in the print finishing stage, giving documents a polished, professional appearance while ensuring durability and usability. Depending on the purpose, volume, and presentation needs, various binding methods are used across industries such as education, publishing, corporate, and commercial printing. Below are some of the most common types of binding:

Selecting the right stitching wire depends on your project requirements, machine compatibility, and desired finish. Keep these factors in mind:

Wire stitching offers multiple benefits:

Compared to glue binding, stitching is more robust and less likely to degrade over time. It’s also more economical than case binding and faster than spiral or comb methods for booklet production.

Proper storage and handling of stitching wire ensure consistent results and extend machine life:

Understanding the role of stitching wire in print finishing can help you choose the best materials and equipment for your binding needs. Whether you’re running a small print operation or managing a large-scale publication project, wire stitching offers a dependable and efficient solution. By selecting the appropriate type of wire, using it properly, and maintaining your equipment, you’ll achieve consistent, professional binding results every time.

Bookmark

Daniel Féau processes personal data in order to optimise communication with our sales leads, our future clients and our established clients.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.