Nails come in different sizes, materials, and shaft configurations to maximize holding power in different projects built with wood. Let this guide help you find the right nail size and type for your project.

Types of Nails

- 01 of 08

Common Nail

:max_bytes(150000):strip_icc():format(webp)/nail-sizes-and-types-1824836_02_common-29524be926ba47efa331959c7f1ea788.jpg)

Credit: The Spruce / Margot Cavin

Common nails are used for general construction and specifically for framing and other structural work.

Common nails have a thick shank, a wide head, and a diamond-shaped point. They are most commonly used with 2x dimensional lumber, such as two-by-fours. They are thick enough to be strong, but they are also more likely to split wood than thinner nails.

A special type of common nail is the sinker, with a slightly narrower shank and a special head designed to be sunk flush with the surface of the wood.

- 02 of 08

Box Nail

:max_bytes(150000):strip_icc():format(webp)/nail-sizes-and-types-1824836_03_box-3fd934357fa14e6d9c5ea73882a612a0.jpg)

Credit: The Spruce / Margot Cavin

Box nails are similar to common nails and sinkers but have thinner shanks. They are better suited to thinner wood materials, such as 1x (3/4-inch-thick) lumber and exterior trim.

Box nails should not be used for structural projects because they lack the strength and holding power of common nails. The thinner shank of a box nail is less likely to split thinner materials.

- 03 of 08

Duplex Head Nail

:max_bytes(150000):strip_icc():format(webp)/nail-sizes-and-types-1824836_04_duplex-65b3284682e14dd5904a35bf40f75a3d.jpg)

Credit: The Spruce / Margot Cavin

Duplex head nails have two nail heads: one on top, and another slightly lower.

Duplex nails are used for temporary construction, such as formwork for pouring concrete or attaching temporary cleats during roofing. The nail is driven until the lower head is flush with the wood.

When it's time to disassemble the project, the nail can be extracted using the upper head and the claw of a hammer or pull bar.

- 04 of 08

Annular Ring or Ring Shank Nail

:max_bytes(150000):strip_icc():format(webp)/nail-sizes-and-types-1824836_05_ring-9757d0f110084bdfa26f26009a290322.jpg)

Credit: The Spruce / Margot Cavin

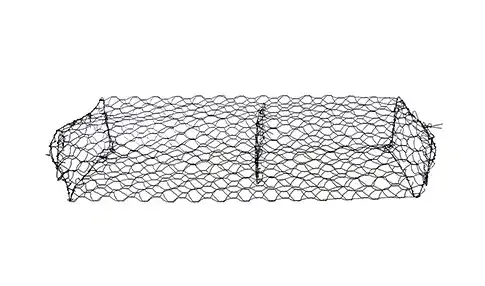

An annular ring nail, or ring shank nail, has rings on its shank for extra grip and additional resistance to pulling out of the wood.

These nails are commonly used for installing subflooring, where the extra holding power can help prevent floors from squeaking. Similar nails that may have rings include drywall nails or deck board nails, also for improved holding power.

Continue to 5 of 8 below - 05 of 08

Masonry Nail or Concrete Nail

:max_bytes(150000):strip_icc():format(webp)/nail-sizes-and-types-1824836_06_masonry-5b9bf0245bab4301b0b91c831f1c68f9.jpg)

Credit: The Spruce / Margot Cavin

Masonry nails and concrete nails are thick, short, and very strong. They are designed to be fastened into concrete, concrete block, and mortar joints, and are a staple of masonry work.

These nails are made of hardened steel, often with grooves along the length of the nail shaft to help them penetrate hard materials by spiraling as they are driven.

- 06 of 08

Finish Nail or Casing Nail

:max_bytes(150000):strip_icc():format(webp)/nail-sizes-and-types-1824836_07_casing-494f4eaf2daa4c808696d9be77451cb2.jpg)

Credit: The Spruce / Margot Cavin

A finish or casing nail has a small, slightly rounded head slightly bigger than the nail shank. The head is designed to accept the pointed tip of a nail set, making it easier to countersink the nail without slipping.

A casing nail is essentially a large finishing nail. It is often used for installing exterior trim boards and nailing door frames and trim. Casing nails are commonly galvanized for corrosion resistance. The nail head is tapered and may be set flush or just below the wood surface.

- 07 of 08

Brad Nail

:max_bytes(150000):strip_icc():format(webp)/nail-sizes-and-types-1824836_08_brad-089cb9b5f4e44a139d28661ca90ec456.jpg)

Credit: The Spruce / Margot Cavin

Brad nails (or brads) have thin shanks similar to finishing nails.

Brad nails are used in light woodworking. Because of the small shank diameter and the small head, these nails reduce the possibility of splitting the wood.

Because they are difficult to drive by hand, brad nails are typically used with a nail gun.

- 08 of 08

Roofing Nail or Clout Nail

:max_bytes(150000):strip_icc():format(webp)/nail-sizes-and-types-1824836_09_roofing-51a18da686034040877cc9faf0c347a4.jpg)

Credit: The Spruce / Margot Cavin

Roofing nails, sometimes called clout nails, have a short shank and a wide, flat, thin head.

Roofing nails are used to fasten shingles, roofing felt, or sheet metal to wood. The shanks can be smooth or ringed for increased pull-out resistance.

Penny Nail Names

The penny nail system uses names like 10d, 16d, and so on. The penny system refers to nail length. Each higher number represents a 1/4-inch length increase in the nail.

| Penny Name | Length (Imperial) | Length (Metric) |

| 2d | 1-inch | 25.4 mm |

| 3d | 1-1/4-inch | 31.7 mm |

| 4d | 1-1/2-inch | 38.1 mm |

| 5d | 1-3/4-inch | 44.4 mm |

| 6d | 2-inch | 50.8 mm |

| 7d | 2-1/4-inch | 57.1 mm |

| 8d | 2-1/2-inch | 63.5 mm |

| 9d | 2-3/4-inch | 69.8 mm |

| 10d | 3-inch | 76.2 mm |

| 12d | 3-1/4-inch | 82.5 mm |

| 16d | 3-1/2-inch | 88.9 mm |

| 20d | 4-inch | 101.6 mm |

Nail Points

A nail point is the end of the nail: the part that is hammered or driven into the material.

- Diamond point: The most common type of nail point is a diamond-shaped point. It makes the nail easy to drive and minimizes the possibility of splitting the wood.

- Blunt point: A blunt point makes the nail more difficult to drive, but it is designed to avoid splitting the wood. Some carpenters dull the nail tip to prevent splitting the wood.

Nail Shanks

The nail shank is the long part of the nail. It is the strongest part of the nail, with the most holding power.

- Smooth shank: A smooth shank drives in easily but pulls out just as easily.

- Spiral shank: A spiral shank, used for hardwoods, rotates as it is driven into the material which prevents it from pulling out easily.

- Ring-shank: A ring-shank locks into the wood fibers as it's driven in, mostly with softwoods, to secure it from pulling out.

Nail Heads

The nail head is the flat, usually round section at the opposite end of the tip. Common flat heads offer a large striking surface.

- Checkered nail heads: Checkered flat heads with a grid pattern prevent the hammer from slipping off the head when striking.

- Countersunk and cupped heads: These nail heads are conical, so they can be easily driven just below the surface to create a smoother finish.

Nail Coatings

Special coatings lubricate the nail shank to improve strength and driving ability. An uncoated nail is often called a bright nail.

- Zinc: Galvanized nails coated with zinc offer protection against rust.

- Vinyl: Vinyl coatings also increase drive and holding strength.

- Phosphate: Black phosphate coatings are used for indoor nails to help them adhere better to some interior materials.

Types of Metals for Nails

Nails are made from ordinary steel, stainless steel, brass, copper, or aluminum. Most construction nails are steel, and often they are coated.

Nails for outdoor use are often galvanized or hot-dipped with a zinc coating to improve their weather resistance. With pressure-treated lumber, hot-dipped nails are essential to prevent the corrosion caused by the chemicals used in the lumber.

Stainless steel is also used for outdoor applications, though stainless steel nails are considerably more expensive than zinc-plated nails.

- Which nails are the most durable?

Stainless steel nails are the most durable nails, especially when used outside for projects like fences, decks, or sheds. But stainless steel nails are more expensive than galvanized nails or zinc-plated nails.

- What is the difference between framing and common nails?

Framing nail shanks are thinner and they have thin, almost flat heads. Common nails have a thicker nail shank and thicker heads.

:max_bytes(150000):strip_icc():format(webp)/GettyImages-2203889031-069a526a5e644bcc8bf690b66b2578f4.jpg)

:max_bytes(150000):strip_icc():format(webp)/biggest-mistakes-when-buying-carpet-2908863-04-89149d9c844e4f8697c6e6d0f6c11563.jpg)

:max_bytes(150000):strip_icc():format(webp)/how-to-remove-towel-bar-5221017-hero-01-c6a21614aaeb4e9ca8071b79bd398ef6.jpg)

:max_bytes(150000):strip_icc():format(webp)/Choosing-the-Right-Wire-Nuts-for-Electrical-Connections-3h-b5a9640179dd41c7a0d3dd48dd637474.jpg)

:max_bytes(150000):strip_icc():format(webp)/SPR-grout-sealer-definition-1821387-hero-362aa3feece248a0b475765b8ea0e925.jpg)

:max_bytes(150000):strip_icc():format(webp)/Plastic-Plumbing-Pipe-183508152-58a47c925f9b58819c9c8ac6.jpg)

:max_bytes(150000):strip_icc():format(webp)/Circuit-breaker-GettyImages-183752398-58e657fb5f9b58ef7eaff498.jpg)

:max_bytes(150000):strip_icc():format(webp)/assessing-and-repairing-a-cracked-toilet-2719016-hero-a74466cac0a24cefa33a909b6a6dd67c.jpg)

:max_bytes(150000):strip_icc():format(webp)/home-interior-workspace-WFHHOW0320-15b81c232c554abba83f3e4f0df5468e.jpg)

:max_bytes(150000):strip_icc():format(webp)/solve-water-hammer-issues-844851_hero_19478-3c2a9de26a44477e93cf624f71649aba.jpg)

:max_bytes(150000):strip_icc():format(webp)/analyzing-light-fixture-problems-1152833-hero-5a3b3e1c9fbb43778b89be1cf9673fb9.jpg)

:max_bytes(150000):strip_icc():format(webp)/how-to-drain-a-toilet-2719044-Hero-1ca6be0332b9447bbcfd878a01b2630c.jpg)

:max_bytes(150000):strip_icc():format(webp)/GettyImages-1778015170-fde69238720f479283cce2d32e94a259.jpg)

:max_bytes(150000):strip_icc():format(webp)/Bathroom-plumbing-pipes-GettyImages-172205337-5880e41e3df78c2ccd95e977.jpg)

:max_bytes(150000):strip_icc():format(webp)/GettyImages-175383345-af07bfbbbf6845639b6b4864bc08ebe2.jpg)

:max_bytes(150000):strip_icc():format(webp)/SPR-why-your-toilet-flushes-slow-5218177-hero-586833334fee445593d6d358790afe10.jpg)